Aluminum Die Cast LED Panel FixtureFlood Fixture

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua Ut enim ad minim nostrud

About Us

Welcome Inventive Alloy Cast

Established in 2019 by merging two companies – acme alloy cast (established in 2011) & precision die casting (established in 2014) , We have facility of aluminium pressure die casting, zinc pressure die casting, Brass Pressure Die casting.

We cater to various types of manufacturing industries providing services ranging from product design, development, manufacturing & finishing.

We are a team of well managed, sincere and dedicated engineers and worksmen working towards a common goal of producing quality casting for ultimate satisfaction of the customers.

Aided by the latest technlogy, tools and machinery; we have the ability to design and develop cost-effective components in a speedy and efficient manner.

Milestones

The ideology of starting their own manufacturing company along with the continuance in their legacy, of reselling the parts of the machine which are the heart of a machine, such spare parts according to the customer’s needs and requirements. With the hard work of team inventive and their concentration, dedication, determination this small start up which started in last 10(Ten) years and has now started growing in it’s success all over India. They have succeeded in having happy customers with best and finest quality of products and still continue in doing so.

- Quality Policy

Inventive to be one of the best custom die casters of India, by ensuring maximum customer satisfaction in areas of QCD(Quality, Cost, Delivery).

- Our Mission

To supply our customers with components and tooling that meet their requirements And do business with Best Services.

- Our Vision

Our vision is improvement take the company to the best International standards and make it a reputed business institution.

Our Services

What Service We Offer

We offer precision die design, manufacturing, CNC machining, and finishing services, ensuring high-quality and efficient production. Our expertise includes casting, molding, prototyping, and custom engineering solutions for various industries.

Aluminum Die Casting

Aluminum is cast at a temperature of 650C (1200F). It is alloyed with Silicon 9% and Copper about 3.5% to form the Aluminum Association 380 alloy (UNS A03800).

Engineering

With a team of designers with over years of experience in designing, GAP combines together the latest technologies/platforms and rich experience.

Prototype Models

Our new Rapid Prototyping System can quickly turn computer design data into a 3D prototype.It can help us to communicate and evaluate design.

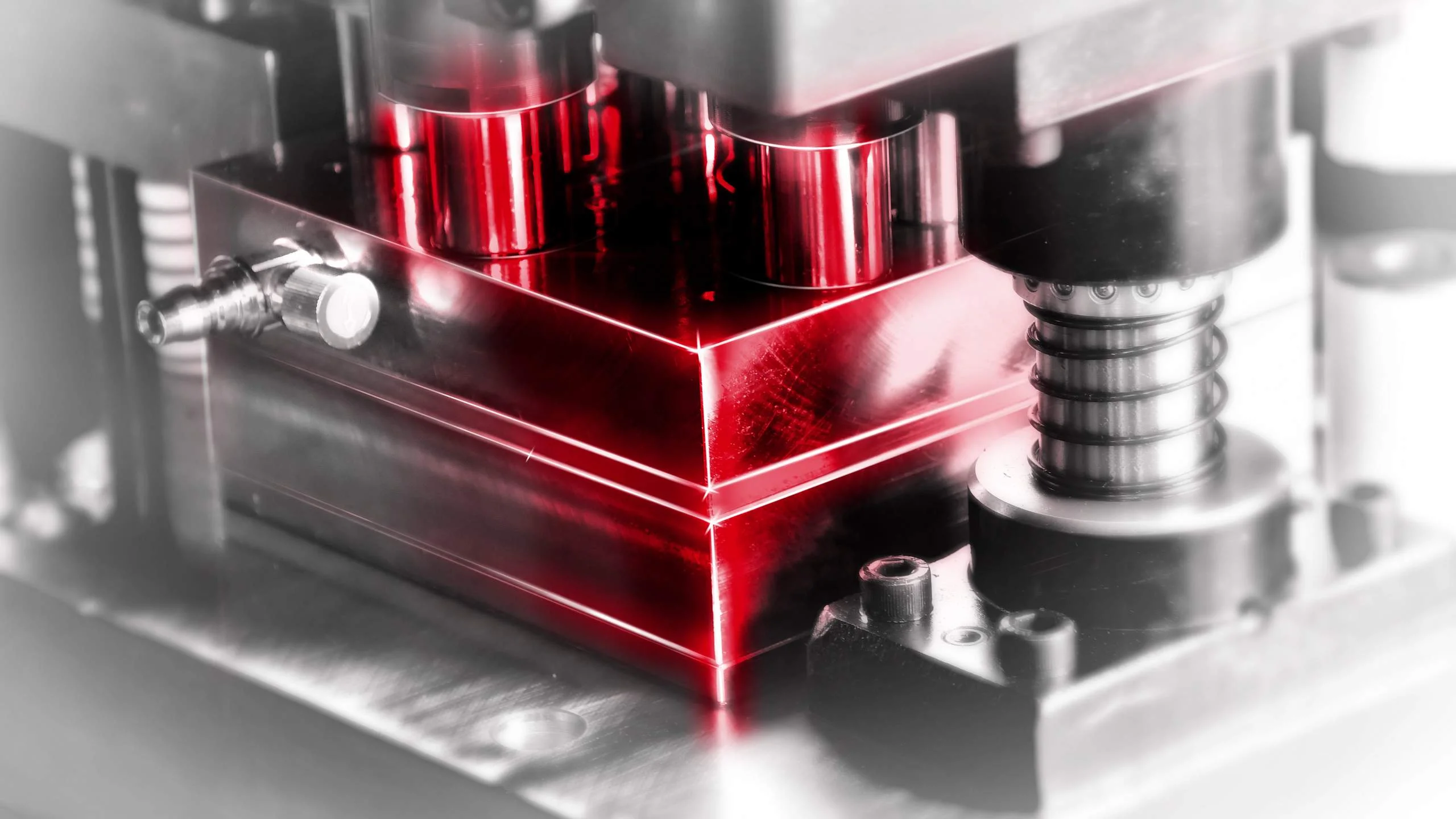

Die Casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created

CNC

CNC (Computer Numerical Control) is a technology that automates machine tools through programmed commands, ensuring high precision and efficiency in manufacturing.

Mold & Fabrication

We design 3D models of parts, molds and components. Engineering is also compatible with Pro Engineering, Auto Cad and all major 3D & 2D design software.

Products

Years Of Experience

Professional Team

Our News

Let’s See Our Latest News

Aluminum Die Cast Flour Mill Part There are numerous different types of alloys that are used to create castings, each...

Aluminum Die Cast Fire Fighting Equipment Most metals used in castings and other metal working processes are not metals at...

Aluminum Die Cast LED Back Light Fixture The alloying agents can be another type of metal or a completely different...